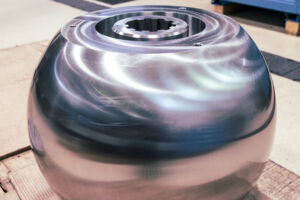

The US Navy submarine fleet is an amazing display of the ingenuity and resolve of this great country. Our nuclear submarine fleet allows our military might to travel great distances undetected and lay in wait on the bottom of a far-off ocean for months if necessary until they are needed to flex our mighty muscles. DK Machine is an approved supplier of valve balls and seats for the US Navy’s submarine fleet directly to the Navy and thru all of their sub-tier suppliers. This is a designation we are very proud of since the lives of hundreds of sailors are on the line every time they bravely put themselves in one of these amazing technological wonders and the ball valve plays many very critical roles on a sub. Submarines use hundreds of different ball valves for everything from the nuclear reactor to the galley sink and many sailors bet their lives on the reliable, safe and silent operation of the valve components we supply. When a ball valve is opened or closed in a submerged submarine application it is sometimes critical that its operation be completely silent. If valve components are not manufactured to exacting precision, they will make noise when they open or close. This noise could spell certain doom for our brave sailors, and we have proven to be the only reliable source for these critical components. We take our responsibility to our troops very seriously and consider it an honor to be do our part to keep them safe and ensure our freedoms. Our facility is secured both physically and digitally to ensure that all proprietary information we are entrusted with stays proprietary. Our facility’s cyber security policy and systems are compliant to DFARS 252.204-7012 for control of FCI and CUI, this is another responsibility we take very seriously.

The US Navy submarine fleet is an amazing display of the ingenuity and resolve of this great country. Our nuclear submarine fleet allows our military might to travel great distances undetected and lay in wait on the bottom of a far-off ocean for months if necessary until they are needed to flex our mighty muscles. DK Machine is an approved supplier of valve balls and seats for the US Navy’s submarine fleet directly to the Navy and thru all of their sub-tier suppliers. This is a designation we are very proud of since the lives of hundreds of sailors are on the line every time they bravely put themselves in one of these amazing technological wonders and the ball valve plays many very critical roles on a sub. Submarines use hundreds of different ball valves for everything from the nuclear reactor to the galley sink and many sailors bet their lives on the reliable, safe and silent operation of the valve components we supply. When a ball valve is opened or closed in a submerged submarine application it is sometimes critical that its operation be completely silent. If valve components are not manufactured to exacting precision, they will make noise when they open or close. This noise could spell certain doom for our brave sailors, and we have proven to be the only reliable source for these critical components. We take our responsibility to our troops very seriously and consider it an honor to be do our part to keep them safe and ensure our freedoms. Our facility is secured both physically and digitally to ensure that all proprietary information we are entrusted with stays proprietary. Our facility’s cyber security policy and systems are compliant to DFARS 252.204-7012 for control of FCI and CUI, this is another responsibility we take very seriously.

Many years ago, we endeavored to develop strict procedures to adhere to the US Navy regulations and requirements for quality assurance and part traceability. These procedures are so efficient and foster such an environment of quality that we decided to implement them across all jobs that pass thru the shop so that all our customers can reap the benefits of assured quality that they provide. Written procedures for everything in the shop from receiving incoming raw materials or tested/coated parts all the way thru the manufacturing process right up to final packaging, weather you are a military contract customer or not- you will benefit from our systems designed to satisfy the requirements of the US Navy including MIL I45208A. All our quality systems are audited regularly thru a system of monthly internal auditing by our own employees and regularly scheduled external audits by the Navy and their sub-tier suppliers. These audits ensure that we are consistently meeting and exceeding the requirements and quality standards set forth. We also maintain tight working relationships with quality assurance inspectors from sub-tier suppliers for military contracts who are in our shop regularly to perform in process and final inspections of our parts. This allows us to stay up to the minute on any changes required in our quality assurance program.

We also supply parts for many other US Military sub-tier suppliers: hydraulic systems for surface to air defense, aircraft carrier catapult and arrest equipment, aircraft landing gear and parts for many other Naval, Ground and Air Based systems. Our customers know they can rely on the quality of our products when the stakes are high, and they can rely on the quality of our systems to prove it. If you need a machine shop to supply any type of parts for fulfillment of military contracts you have come to the right place, give DK Machine a call today to find out how we can help you.

We also supply parts for many other US Military sub-tier suppliers: hydraulic systems for surface to air defense, aircraft carrier catapult and arrest equipment, aircraft landing gear and parts for many other Naval, Ground and Air Based systems. Our customers know they can rely on the quality of our products when the stakes are high, and they can rely on the quality of our systems to prove it. If you need a machine shop to supply any type of parts for fulfillment of military contracts you have come to the right place, give DK Machine a call today to find out how we can help you.